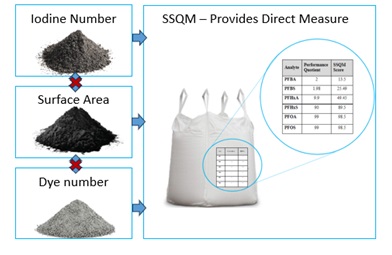

To date, sorbent performance for PFAS immobilisation applications has been assessed using a variety of measures such as Iodine Number, Methylene Blue Number and Specific Surface Area (SSA). Because of the various binding mechanisms for PFAS to sorbents, these tests alone are not able to simulate PFAS binding efficiency for the numerous sorbent media on the market and across a variety of PFAS species (example image B). This has presented issues in the application of sorbents for immobilising PFAS, where the measures used in the specification either are unclear, do not represent performance, exclude key solutions, or potentially result in suboptimal outcomes.

This issue has been the driver behind the development of a methodology to unify and standardise language and analytical measures around how sorbents are characterised.

At present, a number of approaches are inconsistently used across the industry, these include:

- Iodine Number measures such as ASTM, Standard Test Method for Determination of Iodine Number of Activated Carbon, ASTM D4607-14, 2021.

- Specific Surface Area (SSA) akin to ISO 9277:2010

- Determination of the specific surface area of solids by gas adsorption — BET method, 2010.

- Methylene Blue Value such as European Council of Chemical Manufacturers’ Federations, Test Methods for Activated Carbon, 1986

- Various Dye test for Capacity such as those described in Sörengård et al. (2020).

- Sorption/desorption kinetics modelling as described by European Council of Chemical Manufacturers’ Federations, Test Methods for Activated Carbon, 1986.

- Leachability testing such as that in Australian Standard Leaching Procedure (ASLP) tests (Australian Standard AS4439).

All the above-mentioned methods work well to describe the physical and chemical properties of powdered and granular activated carbon products. When these methods are applied to sorbents that are not wholly carbon based such as anion exchange resins, mixed mineral products, organoclays, and other novel sorbents, the iodine number, SSA and dye tests do not necessarily relate to the PFAS sorption of these other products or are not cross compatible. This then means that there is no way to make a comparison between carbon-based products (PAC, GAC) and the other sorbents to compare PFAS sorption efficacy. Further, this provides very little information regards behaviour for the variety of PFAS species usually present on contaminated sites.

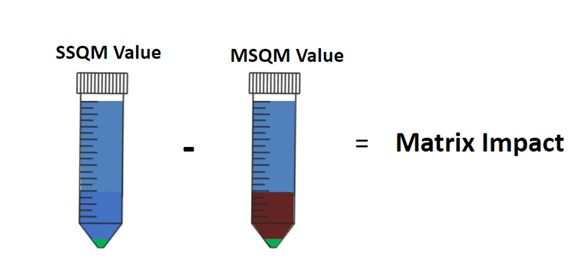

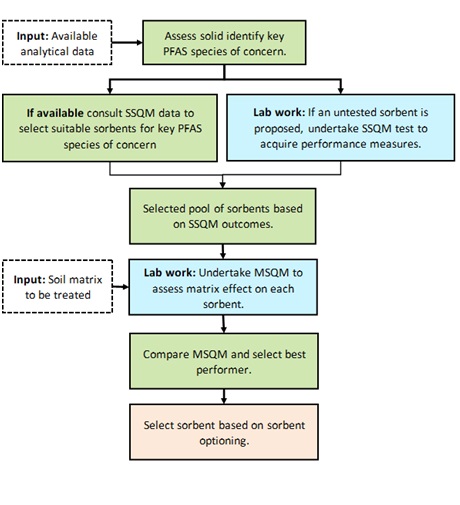

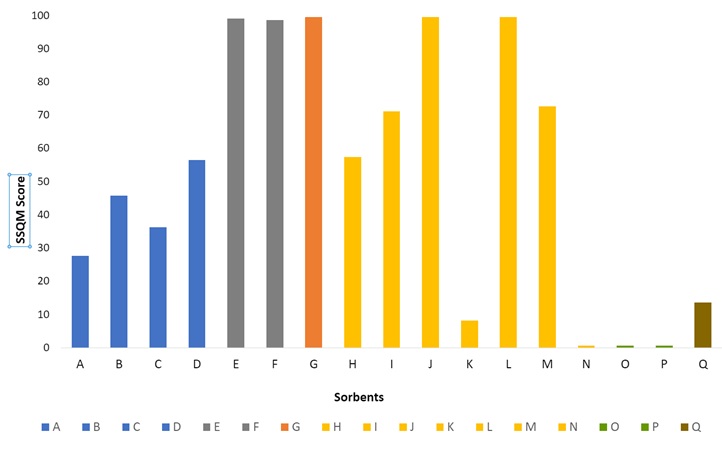

ADE’s Standardised Sorbent Quality Measure(SSQM) method and Matrix Sorbent Qualities Measure (MSQM) method, provide results for PFAS stabilisation efficacy that are directly comparable between sorbent products, regardless of product composition. SSQM can be used alongside more detailed assessment methods such as kinetics and isotherm modelling. Kinetic and isotherm models offer a direct way to determine the sorption and desorption behaviours of PFAS to a sorbent product, which is then comparable to other products. The disadvantage of this method, compared to SSQM/MSQM is that kinetics and isotherm studies require multiple samples to be analysed over multiple time-points, rendering this approach neither cost nor time efficient. Furthermore, for the results to be comparable, studies need to be completed in the same concentration range and experimental conditions, which is often not the case.

By means of comparison, ASLP is a leachability test often used for sorbent performance, and measures contaminant leachability over a set period of time to simulate 100 years in a landfill. The method is only applied to soil or treated soil samples with no easily calculable kinetics information once testing is complete. The data collected from ASLP is useful but does not provide a cross comparable measure and only considers the desorption step once sorption is completed.

Overall, while several methods are available to directly or indirectly characterise sorbent performance, there is at present no harmonised approach, and comparing sorbents with different or incompatible measures to each other and specifications is a common challenge. This impacts decision making and at times drives negative immobilisation outcomes.

Reference – Mattias Sörengård, Erik Östblom, Stephan Köhler, Lutz Ahrens, Adsorption behavior of per- and polyfluoralkyl substances (PFASs) to 44 inorganic and organic sorbents and use of dyes as proxies for PFAS sorption, Journal of Environmental Chemical Engineering, Volume 8, Issue 3, 2020, 103744, ISSN 2213-3437.