Until recently, there was no analytical methodology commercially available for use in the quality control of the soil remediation or blending process, when considering the addition of sorbents for the immobilisation of contaminants such as PFAS. Typically, sorbents are blended into soils at a known percentage weight by weight (w/w) to immobilise contaminants, with the application rate often listed in a treatment specification as determined by a bench scale treatability study.

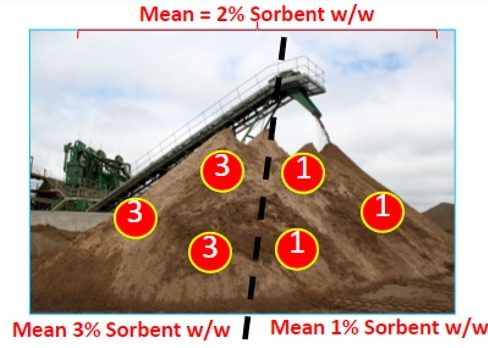

To date there has not been a direct measure to assess if the dosing rate stipulated in a specification was achieved, and how variably it was applied throughout the treated material. This causes quality issues, often resulting in undesirable performance and potential release of contaminants to the environment. Under these circumstances, the immobilisation process can appear not to have worked, but the cause is in fact the poor distribution of the sorbent through the treated material, as opposed to the performance efficiency of the sorbent itself.

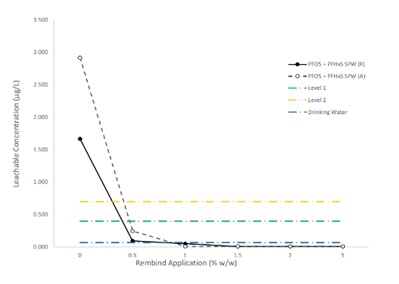

Prior to the conceptualisation of ADE’s Sorbent Application Uniformity Test (SAUT) the approach to quantifying sorbent application for quality control has typically been one that measures efficiency (effective immobilisation) of sorbent by contaminant leachability reduction. The method used for this is the Australian Standard Leaching Procedure (ASLP). These values are compared pre- and post- treatment and only inform contaminant leachability reductions based on sorbent application/efficiency, and do not grant any details regarding sorbent dose accuracy or variation through material.

This use of ASLP is limited by variables such as unpaired pre/post contaminant concentration samples, matrix impacts, sorbent efficiency, sorbent and soil and uniformity. As such this method cannot be used to assess dosing accuracy and or variability, but is a useful measurement for sorbent performance.

Dye methods have been used in the past to characterise sorbents and assess their capacity (via a dye proxy measure) to sorb target contaminants (Sorengard et al., 2020). These do not however assess the dosing of sorbents in the soil or variability thereof, and are instead designed to estimate the sorption capability of sorbent or matrix.

Considering the above, there was a significant need for the development of a robust tool that could measure the mass of sorbent in a soil quickly and cost effectively to allow the measurement of immobilisation blending process quality.

Reference – Mattias Sörengård, Erik Östblom, Stephan Köhler, Lutz Ahrens, Adsorption behavior of per- and polyfluoralkyl substances (PFASs) to 44 inorganic and organic sorbents and use of dyes as proxies for PFAS sorption, Journal of Environmental Chemical Engineering, Volume 8, Issue 3, 2020, 103744, ISSN 2213-3437.